Coordinated by the leading global tyre manufacturer Michelin and uniting 7 industrial partners, 5 Research & Technological Organizations (RTOs) and an innovation cluster into a European consortium in 5 countries, the BlackCycle project aims to enable a massive circular economy of tyres by designing world-first processes to produce new tyres from end-of-life tyres (ELTs).

Officially launched in May 2020, the BlackCycle project involves 13 organisations1 in a unique European public-private partnership that will demonstrate the technical, environmental, and economic viability of world-first circular processes. The consortium will develop specific solutions to produce sustainable raw materials for tyres: ELT collection and feedstock selection, pyrolysis2 optimisation, oil refining and valorisation, furnace process optimisation, and sustainable tyre performance assessment. As early as 5-6 years after the project, close to 1 out of every 2 European ELTs will be incorporated into the only virtuous cycle of this magnitude amongst all industrial sectors for the recovery of end of life products.

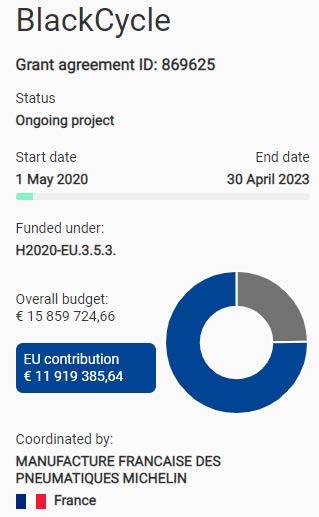

Funded by the Horizon 2020 program, BlackCycle benefits from an overall budget of about 16 M€ with an allocated European funding of about 12M€ (75% of project costs, see Fig. 1). About 35% of the project funding is allocated to SMEs, 15% to RTOs and 34% corresponds to the personnel costs. The consortium covers 5 European countries: France, Spain, Germany, Greece, and Switzerland and includes 7 industrial partners, 5 RTOs and an innovation cluster. Coordinated by Michelin, the consortium has designed an effective governance system involving a steering committee, a cluster synergies board, and a technical support committee.

Context

1.6 billion new tyres are sold worldwide each year, representing more than 26 million tons, and just as many fall into the category of end-of-life tyres (ELT) providing a large and partially tapped potential for material recovery. Today’s ELT treatment processes are not circular and do not result in many raw materials that can be reused in the tyre industry. Furthermore, as there is not enough solution to valorise materials from ELT in the EU, more than half of EU end-of-life and second-hand tyres are exported to far-off countries.

A Circular Economy of Tyres in Europe as a goal

The BlackCycle project aims at creating, developing, and optimising a full value chain form ELT feedstock to Secondary Raw Materials (SRMs), with no waste of resources in any part of the chain and a specific attention for the environmental impact. These SRMs will be used to develop new ranges of passenger car and truck tyres, which will be sold commercially in European and global markets. As a result, the BlackCycle value chain as a lower carbon footprint (see Figure 2), emitting 0.93 kg/CO2/kg tyres less and a lower using of fossil resources, using 0.89 kg fossil/kg ELT less. BlackCycle Press Statement at Project Kick-off

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 869625.

By offering an economically and environmentally viable alternative, BlackCycle will reduce the export of end of life tyres. By relocating end-of-life tyre management and transformation within the EU, BlackCycle is expected to create sustainable jobs inside the EU.

Communication contacts

Michelin

Hervé Erschler | Press Relations Michelin Group

+33 6 70 47 85 04 | [email protected]

Orion Engineered Carbons

Dirk Rechenbach | Vice President Marketing Business Line Rubber

+49 151 120 28 200 | [email protected]

Pyrum Innovations

Pascal Klein | MBA

+49 6831 95948 0| [email protected]

Quantis

Christina Papadimitriou | Sustainability Consultant

+41 21 35 35 910 | [email protected]

CSIC-Instituto de Carboquimica (ICB)

Ramon Murillo | Scientific Researcher and leader of the Environmental Research Group

+34 976 733 977 | [email protected]

CPERI/CERTH

Elli Heracleous | Associate Professor

+30 2310 498 345 | [email protected]

Sisener Ingenieros SL

Pablo Gonzalez | Thermal Department Manager

+34 91 658 68 38 | [email protected]

Aliapur

Stéphanie Lafond | Communication Director

+33 6 14 48 15 42 | [email protected]

Estato Umweltservice GmbH

Alexander Prokein | CEO

+49 9 61 3 06 52 27 | [email protected]

HERA Holding

Javier Lacoma | International Business Manager

+34 932 051 010 | [email protected]

AXELERA

Laura-Mia Grevon | Communication & Event manager

+33 7 72 00 67 89 | [email protected]

Ineris

Karine Grimault | Press & media relations officer

+ 33 6 49 33 49 60 | [email protected]

Fundacion ICAMCYL

Santiago Cuesta | General Director

+34 987 440 481 | [email protected]

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 869625.

2 The pyrolysis process is used to depolymerise organic products and to obtain new raw materials for other processes.